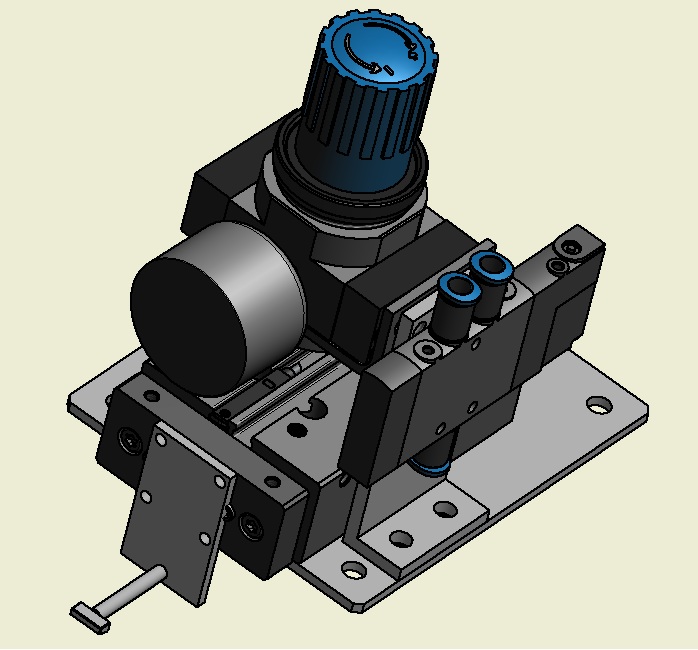

In most industries, pneumatics is a basic component used in intensive production systems, automation and mechanization being necessary for the efficiency of all industrial sectors. Our solutions include, among other things, pneumatic actuators and pneumatic convection and control.

The use of pneumatic actuators is expanded in almost all industrial branches because the systemization of the areas of use of pneumatic drives and controls can be made from the classification of the operations performed. Practically, thorough pneumatic drives, the energy of compressed air is transformed into mechanical work and involves different types of movements.

In a pneumatic system, the air is compressed and then used for various mechanical processes. The air can come from a compressor station or it can be produced locally. By combining several such systems, higher pneumatic actuators systems can be obtained that perform complex functions.

Among the main advantages

of pneumatic actuators are:

- High speed of work;

- Increased productivity;

- Easy adjustment of engine operation;

- Reduced damage risk;

- Compressed air is non-pollutant and non-flammable;

- Maintenance of pneumatic installations is easy as long as there are qualified personnel.

Our team of specialists offers a wide range of services in the field of pneumatics, from design and execution to mechanical machining and technical assistance. We offer flexible solutions customized to all areas where pneumatic actuators are applied. During the design phase, we use the latest technologies so that all the projects we carry out meet the most demanding requirements.

The design services include the inclusion of detailed specifications, design, designing of the construction technology, assembling the pneumatic equipment, testing it and issuing the necessary certificates. Our design services are aimed at new machinery and equipment, as well as the modification of existing ones.

MPH Solutions also offers various mechanical machining services for pneumatic equipment and installations as well as redesign and execution of pneumatic installations to increase and improve their reliability and to streamline production processes.